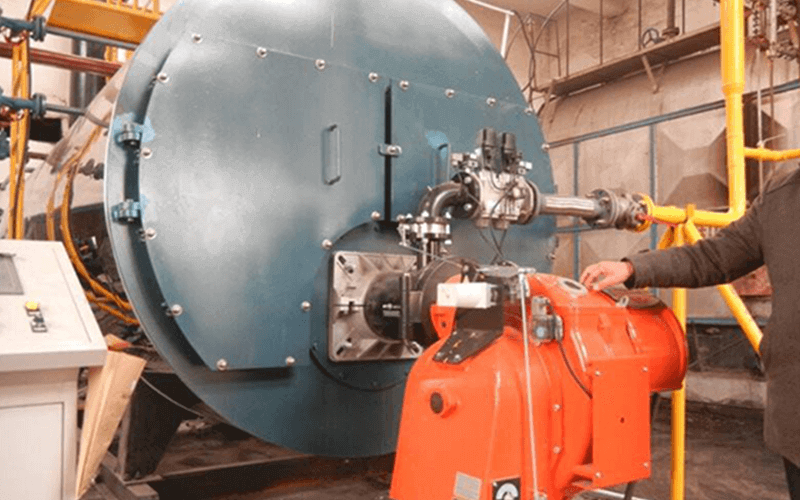

The combustion adjustment of pressure 10 bar gas industrial steam boiler is successful and the load adjustment can be carried out after turning into normal operation. At this time, the combustion situation in the furnace should be observed frequently. The following methods are commonly used to judge the combustion situation of gas-fired boilers.

Judging from the color of the flame and the color of the smoke,

Judge the quality of combustion by the length of the flame.

The combustion is judged from the CO2 content and excess air coefficient in flue gas.

The combustion adjustment method of the pressure 10 bar gas industrial steam boiler is normal combustion, the flame in the furnace is stable and white orange, generally there is a rumbling sound, if the flame beats or has the abnormal sound, should adjust the gas quantity and the air volume in time. If the adjustment still does not improve, the fire should be extinguished to find out the cause, after taking measures to re-ignite.

With the increase of air supply volume, the mixture of gas mist and air is improved, which is beneficial to combustion. However, if the air volume is too large, the furnace temperature will be decreased and the incomplete combustion loss will be increased. At the same time, the heat loss of exhaust gas will be increased and the power consumption of the fan will be increased because of the increase of flue gas. If the air volume is insufficient, the combustion will be incomplete, resulting in carbon deposition at the tail, which is prone to secondary combustion accidents. Therefore, each pressure 10 bar gas industrial steam boiler should pass the thermal efficiency test to determine its economic air volume at different loads. In practice, the stoves usually take into account the ignition of the nozzle and the carbon dioxide or oxygen content in the flue gas. Content to adjust the supply air volume. If it is found that the combustion condition of a nozzle is not good, or if the atomization plate with different aperture is replaced, the air pressure of the supply duct should be kept unchanged, and the opening degree of the duct baffle of the nozzle should be adjusted to normal combustion. If the fuel quantity changes due to the change of the gas pressure in front of the furnace, the opening of the fan baffle should be adjusted to achieve normal combustion by changing the air pressure and air volume of the air supply duct when it is necessary to adjust the supply air volume.

the observation and analysis of all kinds of flame when adjusting the fuel gas. Generally through the fire point adjustment and flame center adjustment to complete the flame adjustment. The ignition point of the gas mist should be close to the nozzle, but there should be no tempering. Early ignition is beneficial to complete combustion and stability of gas mist. However, the fire is too early, too close to the nozzle, easy to burn the nozzle and furnace wall to determine the mouth. Furnace temperature flying gas varieties and atomization quality, as well as air volume, wind speed and gas temperature, will affect the distance and proximity of the ignition point. So if you want to adjust the ignition point, you should find out the cause in advance, and then take targeted measures. When the boiler load is constant and the gas pressure and gas temperature are stable, Should be based on the ignition point wind speed and wind distribution situation.

The change of boiler water level can make steam pressure unstable, even full water or lack of water accident. Therefore, in order to keep the water level fluctuating slightly near the normal water level, the boiler should supply water evenly and continuously as far as possible in order to keep the water level fluctuating slightly near the normal water level. If low water level appears, the combustion should be controlled immediately. All kinds of boilers with different structures have prescribed the minimum safe water level, which must be maintained above the minimum water level limit in the operation of the boiler. The above is manual regulation, small-sized pressure 10 bar gas steam boilers are generally automatic regulation.

3. Steam pressure adjustment pressure 10 bar gas steam boiler operation, must constantly monitor the pressure gauge value, to maintain steam pressure stability. The change of boiler steam pressure reflects the relationship between boiler evaporation and steam consumption. When evaporation is greater than steam consumption, steam pressure increases, and steam pressure decreases when evaporation is less than steam consumption.