The boiler manufacturing industry has been gradually improved and developed in the continuous exploration. In the present boiler market, the Classification Of Gas Steam industrial boilers is clear, but many users who first come into contact with the boilers are still not very clear about the structure and technical characteristics of the boilers. Square fast boiler for you a brief introduction of several representative gas-fired steam boiler.

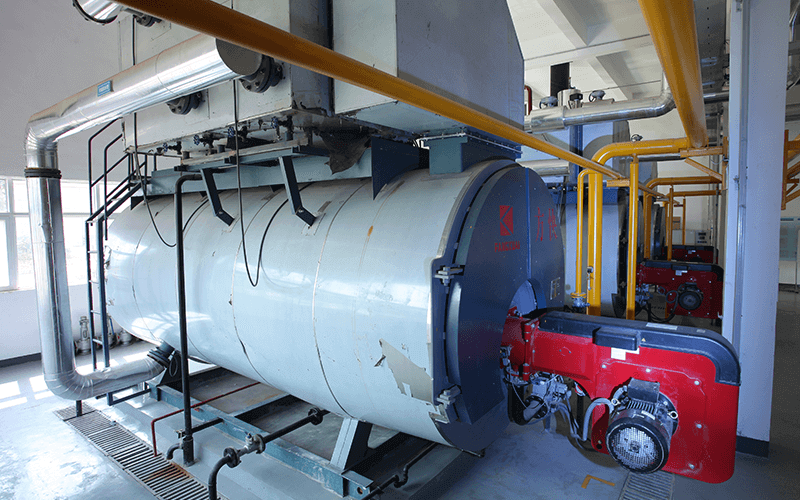

1. WNS series fully automatic fuel (gas) steam boilers

1. The boiler adopts a fast-mounted horizontal internal combustion double-return wet-back smoke structure, the body adopts the bottom-type waveform furnace tank, the return chamber and the waveform furnace tank, the thread smoke pipe is connected. After the high temperature flue gas flame is exothermated in the furnace tank, after the convection heat transfer is carried out through the reburning chamber to the threaded pipe, the high temperature flue gas enters the front smoke box, and the high temperature flue gas enters the energy-saving condenser backward, and after adequate heat transfer, it is discharged into the atmosphere through the chimney.

2, boiler fuel is suitable for natural gas, city gas or liquefied petroleum gas and other oil, gas fuels.

3, the boiler front cigarette box is equipped with movable smoke box cover, disassembly, installation and maintenance is convenient. The boiler is equipped with integral burner, which has the characteristics of fast start-up, high efficiency, high automation and so on. It is suitable for all kinds of places that need to provide steam for life, civil and industry.

4, the boiler is equipped with a complete primary valve instrumentation system, the boiler body valves have inlet stop valve, check valve, main steam valve, safety valve, sewage valve, air valve and the solenoid valve carried by the burner, etc. The main steam valve, the safety valve, the sewage valve, the air valve and the solenoid valve carried by the burner. The measuring points include inlet pressure display, drum pressure display and control, exhaust temperature display, burner temperature and pressure display.

5, boiler combustion and feed water use automatic control, automatic regulation, easy operation, low labor intensity, reliable safety protection device, easy maintenance and maintenance.

Second, SZS series fuel oil (gas) steam boiler

1. The whole boiler has "D" layout structure, double drum distributed up and down, full-mode wall sealed operation, micro-positive chamber combustion, boiler heat dissipation loss and thermal inertia are relatively small, can be started and stopped quickly.

2. The boiler has various protection measures, such as over-pressure protection, automatic regulation of water level, water shortage protection, accidental extinguishment and shutdown protection, program start-up and so on, to ensure the safety of boiler operation in all aspects.

The boiler is compact in structure, small in volume, light in weight and full in output.

4, the manhole device is arranged in front and back of the boiler, and there are inspection doors in the back of the furnace and on the flue, which is convenient for daily inspection and maintenance.

5, boiler assembly design, while meeting the transportation size requirements, the installation cycle is shorter.