Gas Condensing Steam industrial boilers Selection For Steam Supply

The first is the thermal efficiency problem, because this indicator relates to the operating costs incurred during the use of steam boilers.

The second is the steam boiler steaming time problem. The steam boiler steaming time refers to the time taken from the start-up of the machine to the generation of steam that meets the temperature requirements. The shorter this time, the more energy-saving.

The next step is to consider the power of the steam boiler. How to choose the most suitable power? Generally speaking, we must first calculate the steam parameters required per hour, then we should choose 20% higher than the basic steam. Steam boiler power, because we have to consider the factors that may increase the steam consumption in actual operation.

Finally, which type of steam boiler is selected, there are currently types of oil-fired boilers and electric boilers on the market. Due to the current national promotion of “coal to electricity”, more enterprises may choose electric boilers, but traditional electric boilers have problems such as high energy consumption and safety. In contrast, electromagnetic steam boilers are more common than ordinary electric boilers. More than 30% energy saving, multiple safety protection such as water and electricity separation, to ensure its safety.

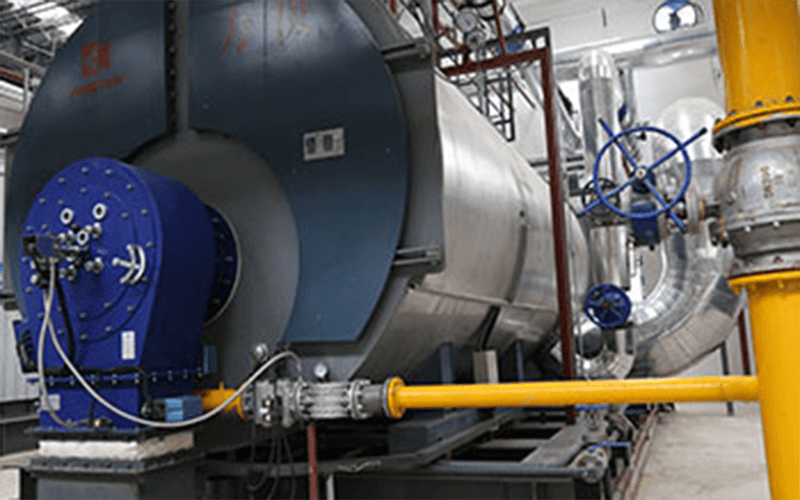

At the same time, the Gas Condensing Steam industrial boilers can also be used for modular installation, which is very convenient for customers. The customer can supply steam according to the actual steam situation, and can also supply steam in multiple parallel units, ready to use. Easy maintenance, saving space and saving infrastructure costs.

The above is the content of "Gas Condensing Steam industrial boilers Selection For Steam Supply" that I shared for you. I hope it will be useful to everyone.